Correct operation method of four-roller plate rolling machine

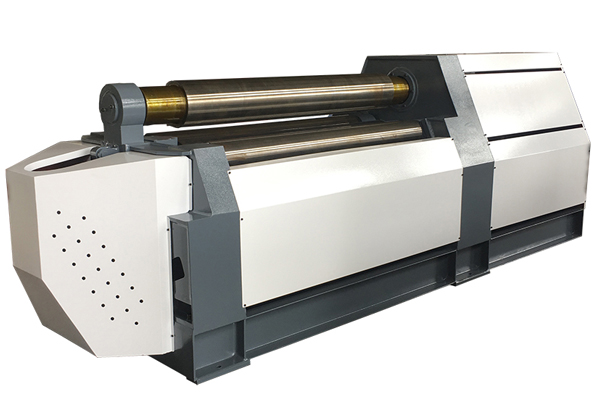

Plate rolling machine is a kind of public forging machine equipment that can bend non-metallic plates into cones, spheres, cylinders or other shapes. This performance is used by large widths. Construction and machine building. The four-roller plate rolling machine is suitable for the bending and forming of sheet metal. It can roll round, arc, and conical workpieces within a certain range. The metal plate can be roughly leveled on this machine.

The four-roller rolling machine and the three-roller rolling machine have different roller movements, but they work on the same principle and also use the principle of three-point fixed circle for rolling with different radius. The position of the upper roller is fixed, and the lower roller linearly moves upward to clamp the steel plate. The rollers on both sides move in a straight or curved line to adjust the curvature radius of the roll.

Any machine should be operated correctly according to the process requirements. Let's talk about the main points of the correct operation of the four-roller plate rolling machine.

(1) The rolling machine must be managed by a special person.

(2) The operator must be familiar with the structural performance and use method of the rolling machine, and the operation can only be performed with the consent of the responsible manager.

(3) Before starting, carefully check whether the safety device is intact.

(4) During operation, it is strictly forbidden to put hands and feet on rollers, transmission parts and workpieces.

(5) After work is interrupted, the clutch should be set to neutral.

(6) Coordinated operation by multiple persons must be directed by a special person.

(7) Overload work is strictly prohibited.

(8) The tilting reset of the upper roller's lifting and reversing bearings and the balance of the upper roller must be performed after the main drive is stopped.

(9) It is forbidden to pile up workpieces and sundries at the work site, and keep the machine tool and the site clean at all times.

(10) After the operation is completed, the power shall be cut off and the power box shall be locked.

Four-roller rolling machine is an important equipment in the production of the enterprise. It must be operated in the correct way during use. Nantong Tel specializes in the production of three-roller rolling machine, four-roller rolling machine and other equipment. Our products are tested strictly in accordance with the process standards and leave the factory. Products serve our customers.